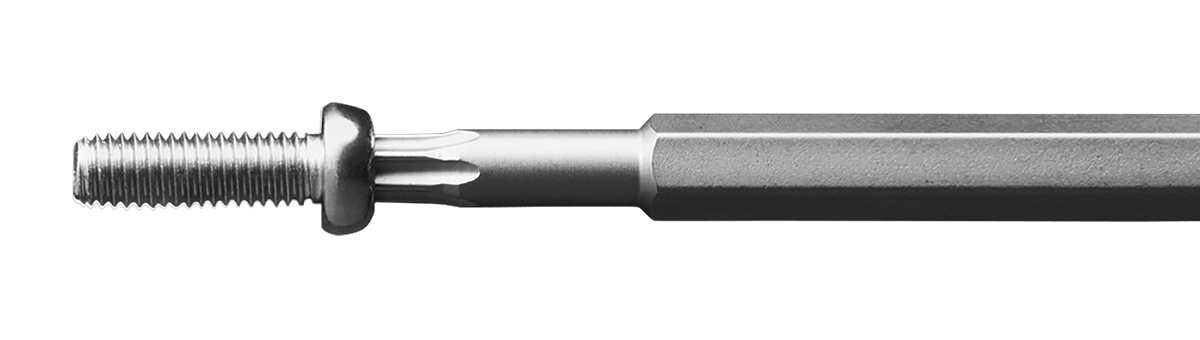

A screw that promotes automation

Reduces loss cost of poor screw fastening to less than one-tenth

Based on the research conducted at an industrial equipment manufacturer that fastens 3.6 million screws of one type (pan-head screw M2.5) per year to investigate screw fastening error occurrence rate and its loss cost.

Comparison table

*Research result in FY2019

| Effectiveness | |||

| Fastening error count including cam out, cross threaded, screw dropping, etc. (3.6 million screws/year) | 500 | 0 | Zero fastening error |

| Rework time (approx. 40 seconds/screw fastening) | 5 hours 33 minutes |

0 minutes | Zero rework hours |

| Labor cost for rework (1,800 yen/hour) | Approx.10,000 yen | 0 yen | Zero rework labor cost |

| Number of bits (3.6 million/year) | 360 bits | 30 bits | Reduced to 1/12 |

| Bit cost (@\1,000/bit) | 360,000 yen | 30,000 yen | -330,000 yen |

Examples

Number of screw types used to assemble a single product

-

Copy machine/Approx. 10 to 30 types

Copy machine/Approx. 10 to 30 types -

Smartphone/Approx. 3 to 10 types

Smartphone/Approx. 3 to 10 types -

Automobile/Approx. 100 to 200 types

Automobile/Approx. 100 to 200 types -

Camera/Approx. 5 to 20 types

Camera/Approx. 5 to 20 types

*The types of screws vary depending on manufacturers.