A screw dramatically changes automation

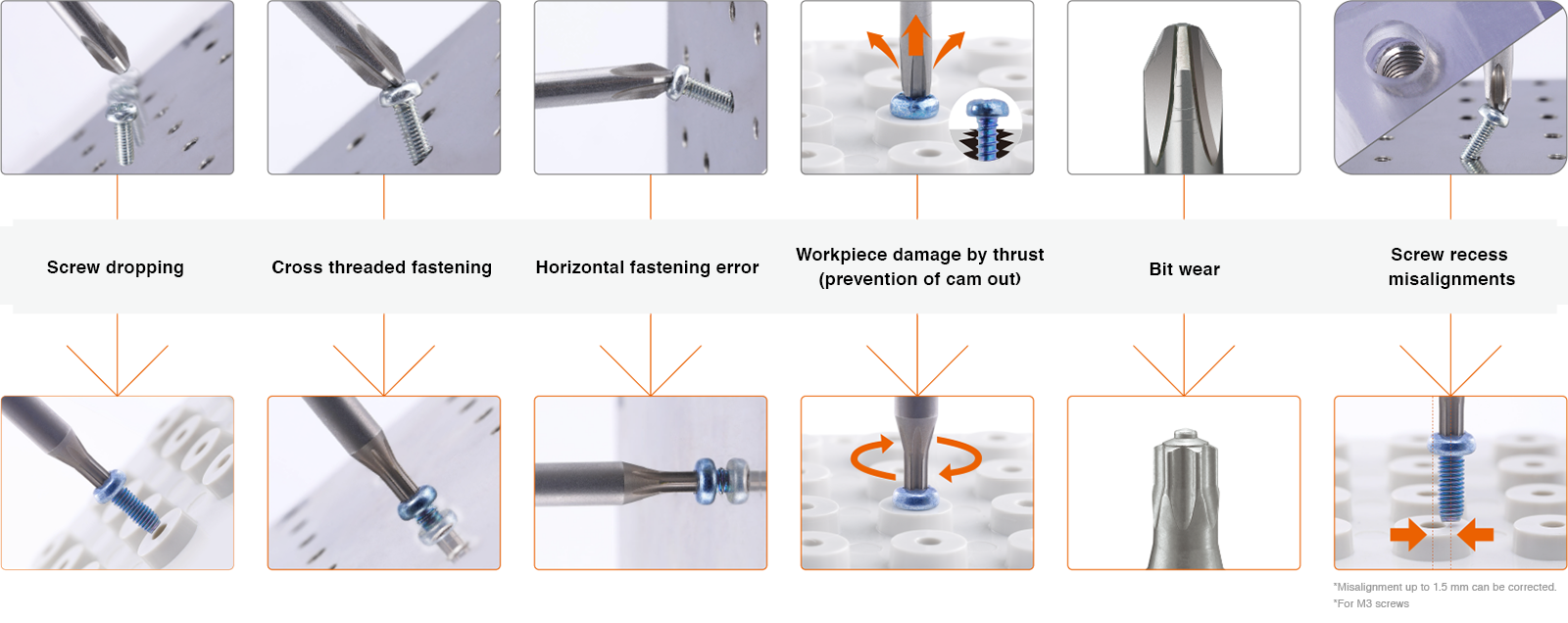

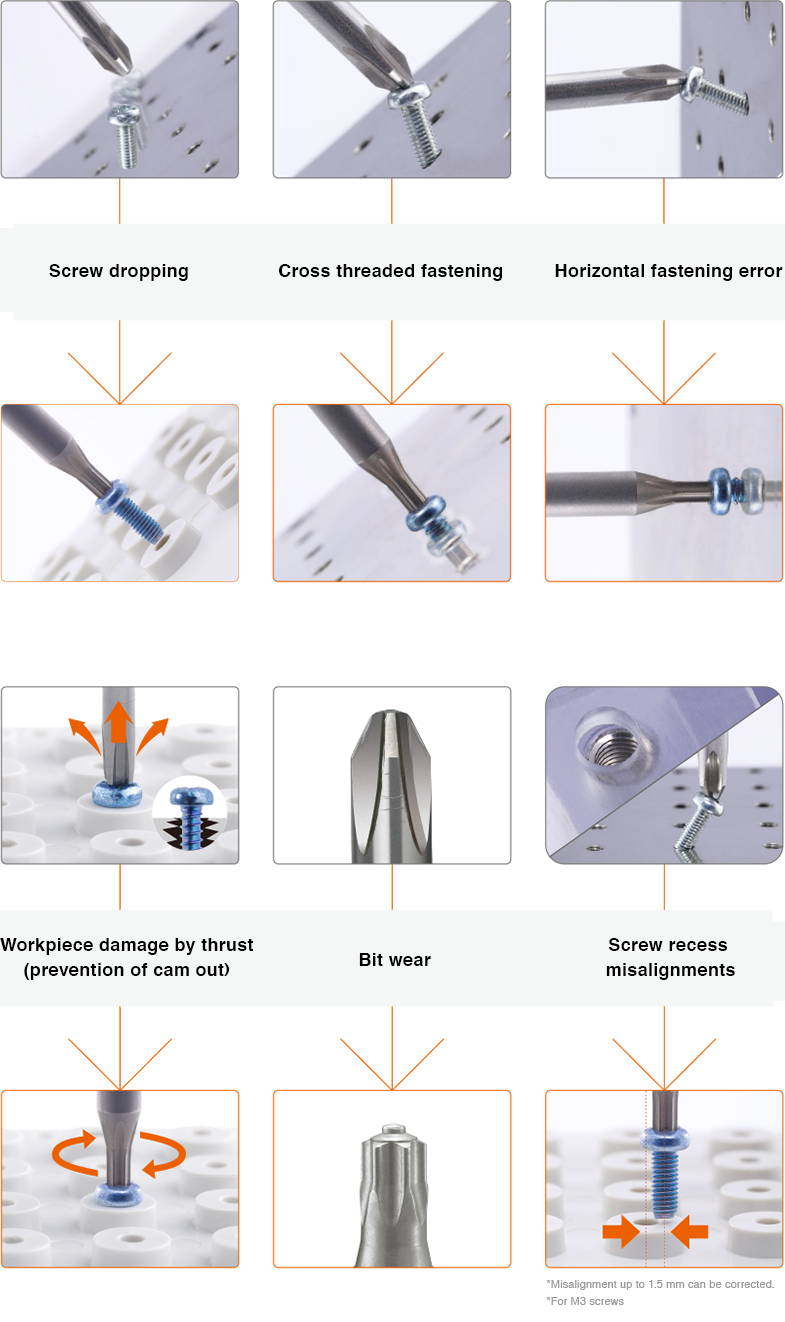

In recent years, automation has been promoted in all manufacturing sites. Among such automation, the screw fastening process causes a lot of problems. The screw fastening process is often regarded as not being so important, but it is difficult to repeat fastening accuracy required by the manufacturing site, and its failure has a great impact on the entire automation line. Screws and screwdrivers play key roles in the screw fastening process in automation. By reviewing the procedures involved, it will be possible to establish an “automation line that never stops”.

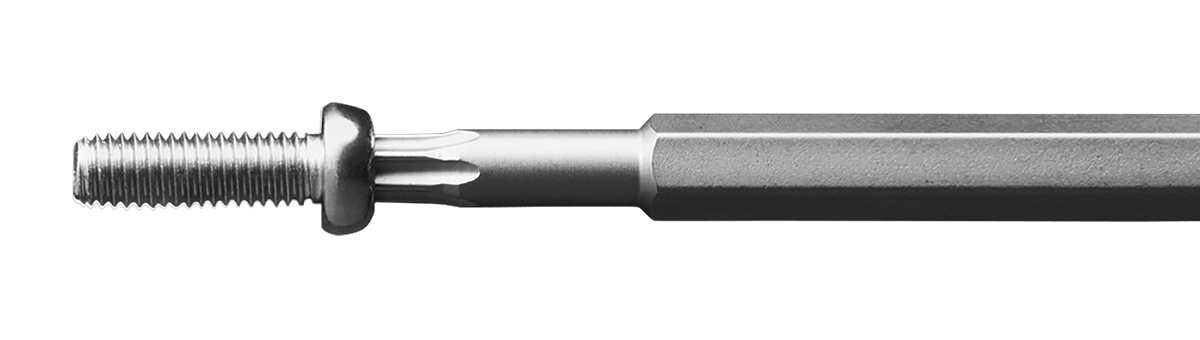

The key for the solution is “fitting performance between screws and bits”

Most of the problems in screw fastening occur when fitting a screw to a workpiece. This problem can be solved by "compatibility between a screw and a bit", in other words, "high fitting performance". Two important points of fitting performance are "the bit is easy to fit into the screw recess" and "there is no wobbling when fastening". Improving this fitting performance will dramatically improve work efficiency, contributing to higher productivity and lower costs.

Screw promoting automation

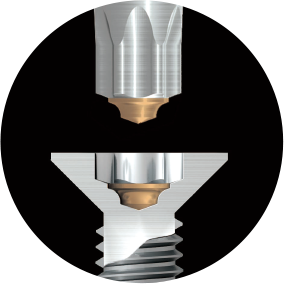

Newly designed

Super Point

(Guide & lock function)

Super Point

(Guide & lock function)

-

1High fitting performanceINTRTORQUE has excellent straightness, which enables highly difficult horizontal and diagonal fastening.

-

2High compatibility with FA equipment and robotsMisalignment (offset) with screw hole hardly occurs and screws can be fastened without rolling.

-

3No thrust is required.Fastening can be done by simply turning the screwdriver in the fastening direction, so there is no damage to the workpiece.

-

4Unparalleled bit durabilityThe durability is 10 times higher than that of cross head bits, which greatly reduces frequency of bit replacement and leads to cost reduction.

-

5Maintains constant conditionsHighly durable bits with high fitting accuracy and easy numerical control ensure stable repeated work.

* Applicable screw sizes: M1.2 to M10 (For other sizes, please contact HIOS.)

Solving Cross Recessed Head Screw Problems in Automation

Cross Recessed Head Screw

INTRTOEQUE®PAT

Automating Data Management of Screw Fastening

One of the advantages of manufacturing automation is easy central management of manufacturing data. In automated screw fastening we propose, the screwdriver itself judges OK or NG of each screw fastening, detects errors with high accuracy, and saves data. This makes it easy to ensure screw fastening quality and traceability management. In addition, since the data can be centrally managed without manual intervention, human workload and errors can be greatly reduced.

High precision screwdriver with OK/NG judgement function

-

1High-precision error detectionThe built-in torque sensor detects screw fastening errors and problems such as insufficient torque and cross threaded fastening.

-

2Maintains stable torqueA highly durable brushless motor maintains stable screw fastening quality.

-

3Visualization of work dataVisualization of the screw fastening process, from quality control to traceability management.

-

4Easy bit replacementA screw type is also available that allows bit replacement without removing the attachment (PGFR).

-

5Vacuum screw pickup attachmentA vacuum screw pickup attachment can pick up screws with different head shapes, and can also handle stainless steel and plastic screws.

It can also be used for difficult screw fastening such as screw fastening in narrow spaces, obstructions and deep recessed holes. (PGFR)

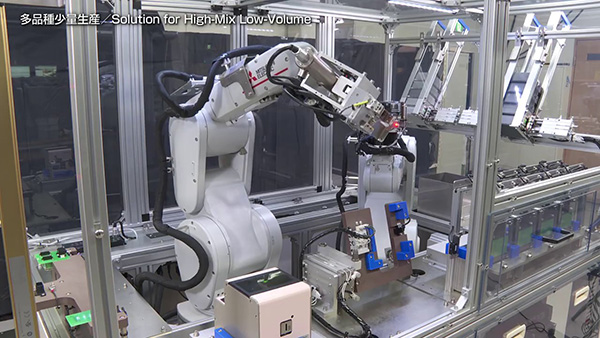

Robot Introduction Support

Robot Introduction Support

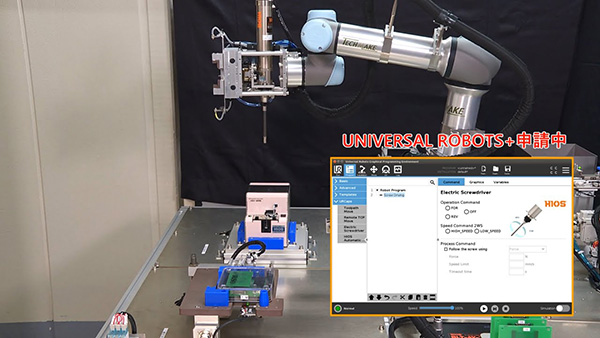

Using plug-ins

Easy connection of an electric screwdriver

We offer plug-ins that allow you to easily connect an electric screwdriver to a robot and use it immediately in intuitive operation. We also support collaborative-type screwdrivers with which humans and robots can work together safely. We can help you reduce the cost of introducing robots, lower barriers to automation, and improve production efficiency.

Automation Alliance Partners

Our products are compatible with robots from various manufacturers because of their high affinity for automation. In addition, we work with robot manufacturers and robot SIers to provide solutions to our customers' problems.

If you have any problems with screw fastening or questions about automation, please contact HIOS.

If you have any problems with screw fastening or questions about automation, please contact HIOS.

Robots (in order of Japanese kana syllabary)

Robot trading company

(in order of Japanese kana syllabary)

(in order of Japanese kana syllabary)

Robot rental/lease

(in order of Japanese kana syllabary)

(in order of Japanese kana syllabary)

Tokyo Century Corporation

Do you have any problems or worries about promoting automation and labor saving through use of robots? Tokyo Century can provide full support from planning to implementation and finance arrangement. [IT Solutions / Automation and labor saving support] [Rental/Robot rental (duAro Screw Fastening Package)]

SIer

(in order of Japanese kana syllabary)

(in order of Japanese kana syllabary)

We will work together with our customers to realize the most advanced automation

For half a century since our foundation, we have pursued labor-saving and automation of screw fastening. We have worked together with our customers to solve many automation projects for automakers, electronics manufacturers, and small and medium-sized manufacturers. From electric screwdrivers to a single screw, we provide the most advanced screw fastening automation solutions for your manufacturing site.

Please contact us for inquiries.