Feature

Download

*DELTA PT is registered a trademark of EJOT.

DELTA PT, designed for thermoplastics, has special threads and roots.

The threads go into thermoplastics sharply and reduce damage of thermoplastics.

Because it can be tightened repeatedly, it is great for recycling and maintaining your products.

Also, it prevents crack in boss and needs no metallic inserts which is costly to put in and take out.

Additionally, it requires thinner wall of boss and your products could weigh less.

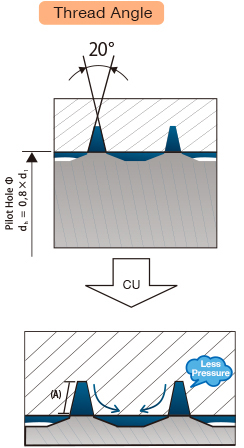

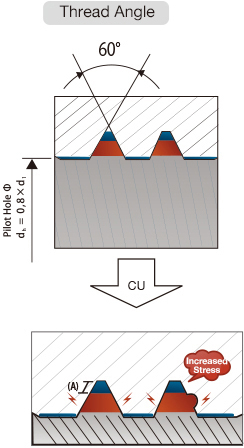

Shape comparison

DELTA PT®

Minor Dia of External Thread:Deep

- Displaced material is accommodated entirely into the specially designed root.

- High flank coverage and minor contact pressure

- Less radial stress and frictional resistance

- Damage free material forming

Other company's tapping screw (sheet metal 60°Flank Angle)

Minor Dia of External Thread:Shallow

- Due to the straight designed roots, there is not enough space for displaced material, causes crack in boss.

- Small flank coverage and high contact pressure

- High radial stress and frictional resistance

- Boss Cracking

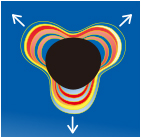

Cross-section view of Thread Part

Cross-section view of Thread Part:Round Shape

Stress is balanced and transmitted evenly.

- Stable

- Less damage to thermoplastics

- No Boss Cracking

Cross-section view of Thread Part:Triangular Geometry

Stress is transmitted concentratedly in 3 directions.

- Unstable

- Damage thermoplastics

- Boss cracking

Comparison in repeat assembly

40times:Less damage

- Can be tightened repeatedly.

- Great for recycling your products.

7times:Damage easily

- Unsuitable for repeat assembly

Comparison in boss cracking

No Boss Cracking

- No Metallic Insert needed

- Thinner boss wall

- Material and weight saving

Boss Cracking

- Increased stress causes boss cracking

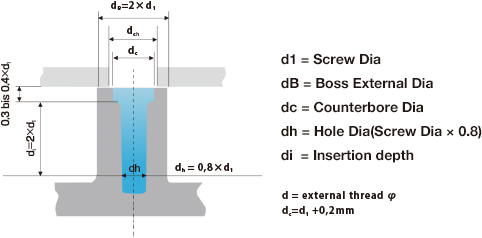

Recommended Boss Design