Do you have anxiety when fastening screws?

JUKUREN eliminates all anxieties about screw fastening.

Digital screwdriver that drives DX.

Error detection and data management of

screw fastening are all automated.

screw fastening are all automated.

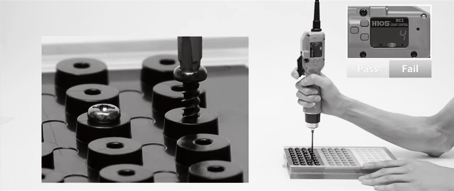

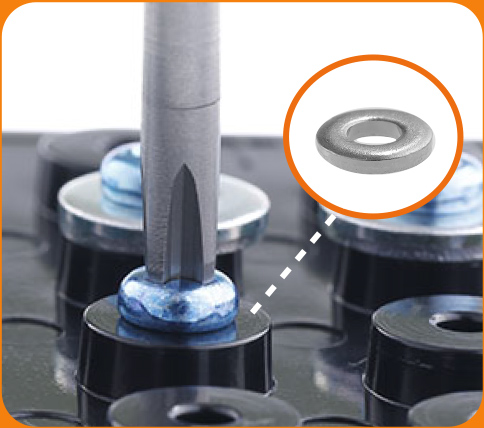

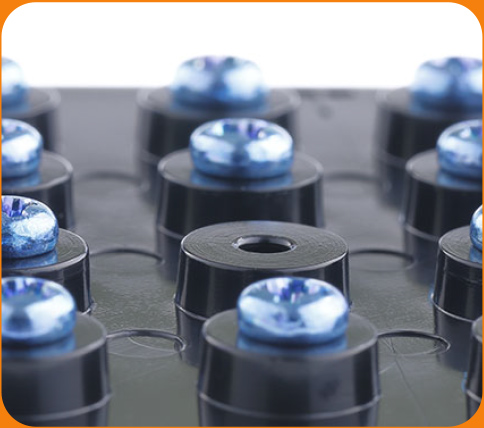

Conventional screw fastening work often relies on the experience and intuition of the worker, who determines if the screw has been fastened correctly. Thus, the quality depends on the skills of the individual. To keep consistent fastening quality regardless who does it, automation and digitalization is the most effective way, and it becomes possible with this JUKUREN. By reading the signals transmitted from the motor and checking the number of pulses, the screwdriver itself judges the screw’s seating condition that is barely detected with a visual check. As a result, anyone can efficiently perform proper screw fastening.

Major Functions

Examples of Error Detection

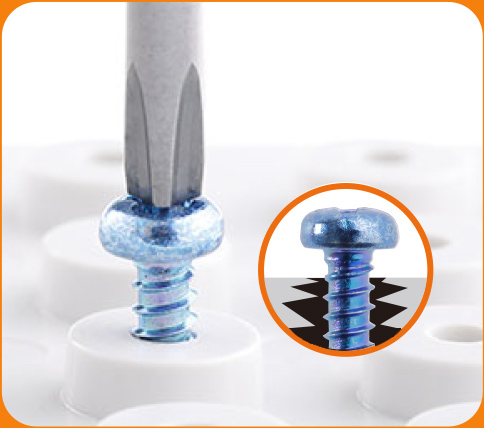

Instantly detects errors that are difficult to detect visually!

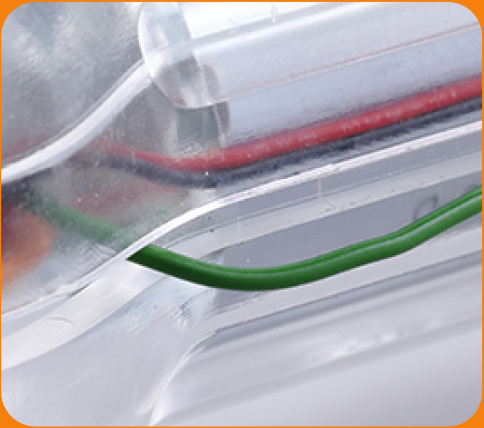

Oblique fastening

Cam out

Seized part

Stripped screw hole

Wrong pitch

Missing part

Missing screw

Unseated screw due to

deep hole or obstacle, etc.

deep hole or obstacle, etc.

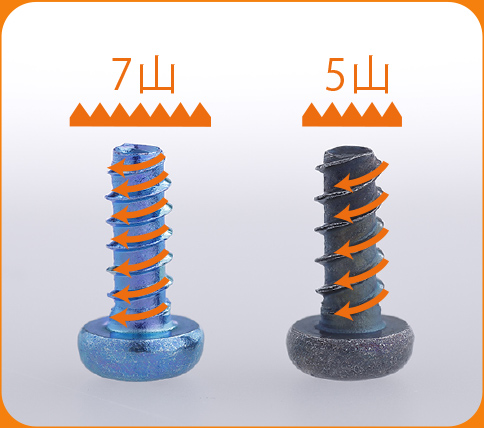

Mixture of wrong

type of screw

type of screw

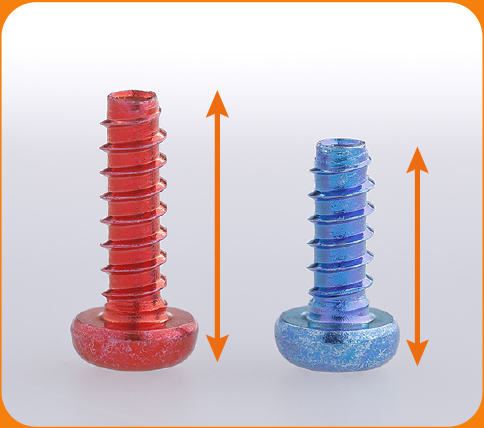

Wrong length

Use Case Video Gallery

BLG-BC2 Lineup

BLG-7000BC2-GT

(with handgrip)

(with handgrip)

BLG-7000BC2-GT

(with stand)

(with stand)

Specifications

| Start type | Lever | Push/Lever | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Model name | Low torque | Hi-speed rotation | Hi-speed rotation | Hi-torque | Hi-torque | Hi-torque | |||

| BLG-4000BC2 | BLG-4000BC2-LT | BLG-5000BC2 | BLG-5000BC2-15 | BLG-5000BC2-18 | BLG-5000BC2-HT | BLG-7000BC2 | BLG-7000BC2-GT | ||

| Output torque range | N・m | 0.1 - 0.55 | 0.03 - 0.2 | 0.2 - 1.2 | 0.3 - 1.0 | 0.5 - 1.5 | 0.5 - 2.0 | 0.7 - 2.8 | 2.0 - 5.0 |

| Unloaded rotation speed (r.p.m) ±10% |

HI | 1,000 | 1,000 | 1,000 | 1,500 | 1,800 | 730 | 1,200 | 600 |

| LOW | 690 | 690 | 690 | 1,000 | 1,200 | - | 800 | - | |

| Screw size guide | Machine screw | 1.4 - 2.6 | 1.0 - 2.3 | 2.0 - 3.0 | 2.3 - 3.0 | 2.3 - 3.0 | 2.0 - 4.0 | 2.6 - 5.0 | 4.0 - 6.0 |

| Tapping screw | 1.4 - 2.3 | 1.0 - 2.0 | 2.0 - 3.0 | 2.0 - 2.6 | 2.0 - 2.6 | 2.0 - 3.0 | 2.6 - 4.0 | 4.0 | |