Equipped with a wireless communication function, the measured torque waveform is graphically displayed on a large display. Visibility and operability have dramatically improved.

-

Sending and receiving data wirelesslyEquipped with the first measured torque data transfer function in the series as standard. The measured torque data can be transferred by connecting wirelessly to a control device such as a PC or PLC.

-

Highly visible displayThe large display clearly shows the measured torque value and waveform, ensuring high visibility in a bright environment.

-

Remote operation from an external deviceThe mode and threshold can be changed from an external device, allowing more convenient and efficient operation.

-

Safe torque controlFeatures a PASS/Fail judgment function to judge the measured torque value. It supports daily quality control tasks in a production line such as screwdriver torque adjustment and setting.

-

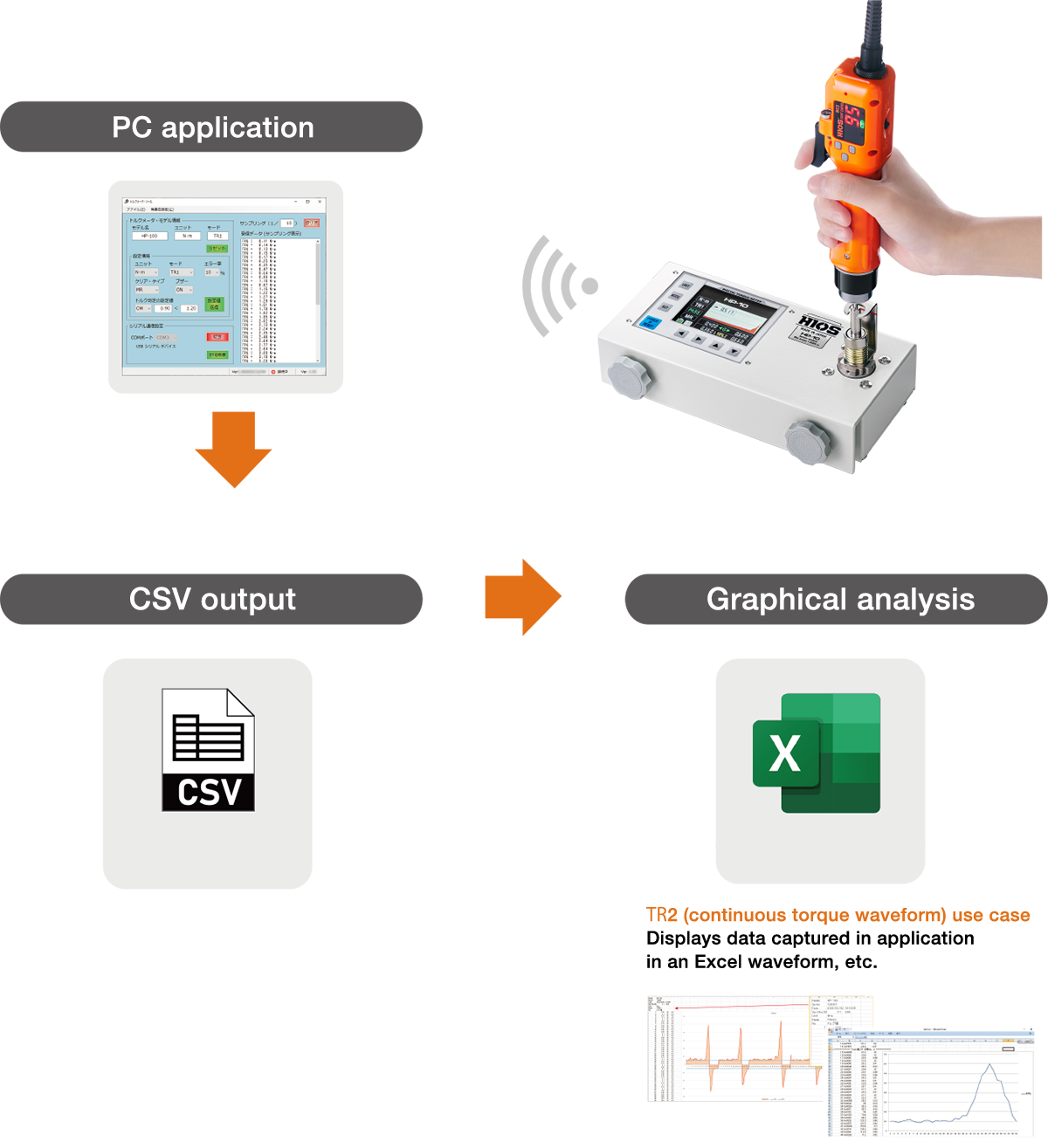

Data collection with specialized applicationsProvides applications that facilitate torque management data collection in a production site. Supports productivity improvement, predictive maintenance, and quality traceability.

Display and Measurement Mode

The torque measurement value is displayed in waveform, and the PASS/FAIL judgment setting can also be visually checked on the display. The measured value, work rate, torque value, etc., are displayed in an easy-to-see way, supporting the improvement of work efficiency.

1

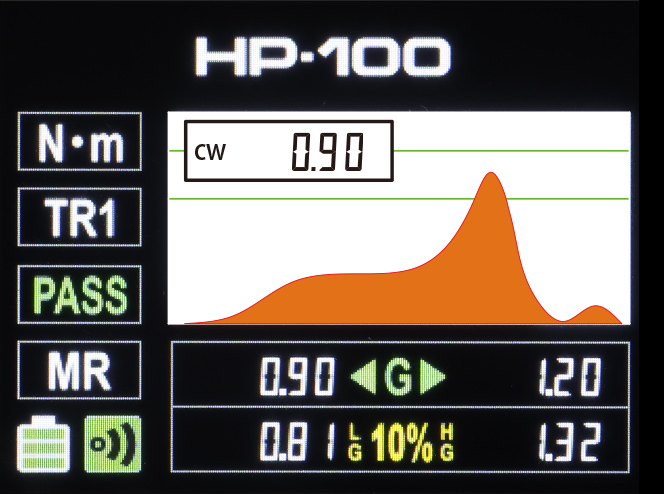

TR1 (Torque waveform)

Fluctuations in the torque from the start to the end of measurement are displayed in a waveform, and the maximum torque value is displayed as a fixed numerical value. When the load is out of the measurement range, the measurement is terminated.

2

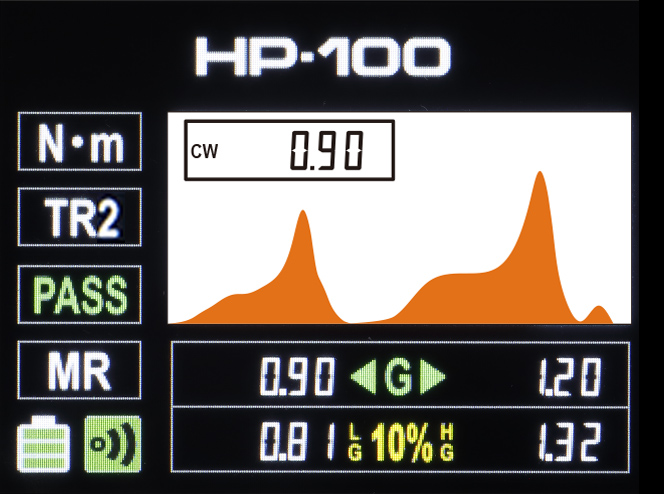

TR2 (Continuous torque waveform)

The value of the load applied to the detector is displayed. Even if the load is outside the measurement range, the waveform data can be measured continuously. You cannot use PASS/Fail judgment.

3

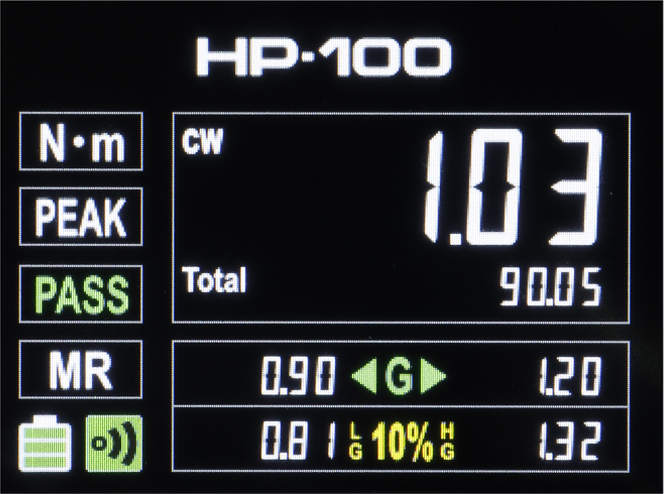

PEAK

The highest actual measured value (peak value) during measurement is displayed. When CCW is selected, a minus sign is displayed.

Sending and receiving data wirelessly

Sending and receiving data wirelessly

Measured torque data transfer function is displayed as standard. Data transfer capability has been enhanced by embedding wired or wireless communication. Both communication methods support the same types of data. You can also control HP Series settings from an external control device. New design features improved functionality and usability, such as changing modes and thresholds, making it easier to use for beginners.

-

●Measurement data outputThe measured torque data can be transferred to a PC or control device. For example, there are various connection methods such as using wireless technology or connecting a USB cable to a PC. You can also set the instrument from an external control device.Connection methods: Bluetooth/USB/RS-232C(optional)

-

●Collection and accumulation of measurement dataThe measured data is transferred to the PC and the data can be easily collected and accumulated through the application. The data can also be exported to a CSV file to be used for evaluation and analysis tools.Supported OS: Windows 10/Windows 11

Lineup

Specifications

| Model name | HP-10 | HP-100 | |||

|---|---|---|---|---|---|

| Interface | Bluetooth (Standard) |

RS-232C (Optional) |

Bluetooth (Standard) |

RS-232C (Optional) |

|

| Meas. range | N・m | 0.015-1.000 | 0.15-10.00 | ||

| N・cm | 1.5-100.0 | 15-1000 | |||

| Min. display unit | 10digit ※1 | ||||

| Meas. Mode | PEAK, F.PEAK (First PEAK), TR1 (torque waveform), TR2 (continuous torque waveform) |

||||

| Meas. Direction | Right-hand screw, left-hand screw | ||||

| Meas. Accuracy | Within ±0.5% (F.S.) | ||||

| Charging and scalability | Supports the following with a micro USB Type-B port: ・Charging ・Data transfer (USB 2.0: up to 480Mb/s) |

||||

※1 About digit

The digit is displayed without decimal point.

[Examples] 0.001=1 digit, 0.025=25 digit, 0.10=10 digit, 1.25=125 digit