"DM Driving" high-performance electric screwdrivers support people-centric workplace

Ricoh Industry

Tohoku Plant

Pursuing ease of work and productivity

Ricoh Industry’s Tohoku Plant was established as Tohoku Ricoh in 1967. Upon reorganization as Ricoh Industry in 2013 by consolidating the production functions of Ricoh Group companies, Tohoku Plant has produced commercial printers, key parts, and other products.

As one of the core plants of the Ricoh Group, the plant is actively implementing plant management, with state-of-the-art facilities such as outdoor unmanned transport vehicles and local 5G on its vast premises overlooking the JR Tohoku Main Line and Shiroishi River, a branch of Abukuma River.

This plant management scheme is based on “Ricoh Way Production”. The “Ricoh Way” implies production activities aligned with 12 key criteria, including KAIZEN, innovation, teamwork, QCD, digital technology, sustainability, and enhancement of the working environment, etc.

Notably, they engage in autonomous KAIZEN activities throughout the plant, including 5S activities from the viewpoint of women, initiatives to improve the working environment and to hold regular case study share meetings, to provide learning opportunities. These initiatives not only improve efficiency but also lead to work style reforms, creating benefits for both the company and the workers.

In 2024, as its initiatives to promote digital manufacturing and reform from the viewpoint of the workers on-site were recognized, the plant was awarded the Factory Management Award at the 2024 GOOD FACTORY Award, sponsored by the Japan Management Association (JMA).

Utilize diverse talents by leveraging digital power

This work also involves workers other than full-time employees, such as temporary workers and subcontractors. Unlike full-time employees trained by the company, who understand and implement Ricoh's unique manufacturing practices, it is extremely difficult to get all the workers with various backgrounds and values to perform the high-quality work Ricoh demands.

Daiki Saito, Director of the Printer Production Division, and other members of the Technical Innovation Office of the Production Technology Center solved this problem with digital power. Mr. Saito, who played a leading role in implementing DM to the Tohoku Plant, digitally visualized the optimal processes for production and created operation manuals, to assure stable quality regardless of the skill levels of workers.

“To deliver high-quality products, it is essential to stabilize assembly quality at the production site. To achieve this, we first had to visualize the processes digitally. In particular, it was urgent to digitize screw fastening, which would require a lot of labor in the assembly process and be prone to defects in the number of screws to be fastened and torque control.”

So, HIOS's new brushless electric screwdriver “JUKUREN” series was chosen. With its built-in pulse system, the screwdriver counts the number of motor rotational pulses and torque from start to completion of the screw fastening. This makes it possible to detect screw fastening problems in real-time, such as “screws not fastened properly” or “screw size is wrong”.

Mr. Saito says, "At that time, although there were a variety of electric screwdrivers available, it was difficult to find the right one with the performance and specifications required for digital manufacturing that the company was seeking. Then we found JUKUREN of HIOS ".

The catch line adopted by HIOS upon the launch of JUKUREN was "Anyone can be a skilled worker." This perfectly aligned with the vision of the Tohoku Plant of Ricoh Industry to “leveling work by diverse talents”. JUKUREN helped the production technology members of Ricoh Industry to further “sophisticate and digitalize the screw fastening process.”

Quality assurance and workload reduction

The main purposes of the Work Support Navigation System are to shorten the learning period and reduce the workers’ workload. It is used for processes that require a large number of assigned man-hours and are difficult.

Tools such as JUKUREN are connected to a PC. Based on the work steps registered in a database, instructions are given to every worker via text, illustrations, and audio so that he/she can understand the contents of work, cautions, and inspection items by looking at the screen. In addition, the work results of the workers are collected as logs and uploaded to the cloud in real-time. This clarifies the potential for work improvement and optimizes the production with a shorter lead time.

The work process assurance system is used for processes with large production volumes that do not take much time to master. The tools are connected to the control unit based on an inexpensive and highly extensive single-board computer to be used standalone.

This system uses text and audio to communicate the work steps registered in the setting file to the worker when there is a possibility of an outflow of a defective product. In this case, the instructions are minimal, and only the keywords of the work are concisely conveyed. Work results are also uploaded to the cloud.

Mr. Saito says, “Both systems use sensor detection and signal reception from the tools to determine whether the work has been successfully completed. If there is an abnormality, such as skipping any step, an alert is sent immediately and the work cannot proceed to the next step. Detailed screw fastening data provided by JUKUREN is very useful. ”

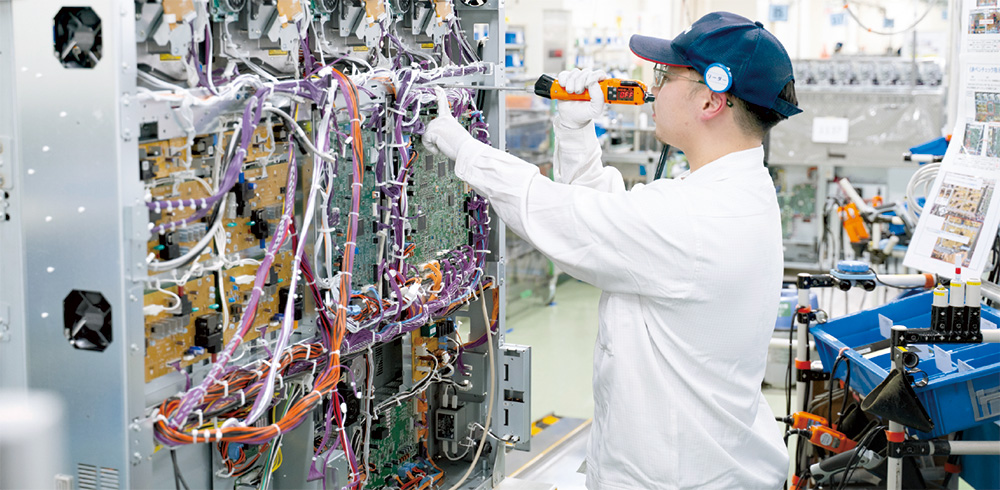

At the production sites, each worker works accurately and smoothly using monitors. In the screw fastening operation, multiple JUKURENs, color-coded according to screw type and fastening torque, are used to quickly assembling parts.

When we hear from a female worker who is engaged in the assembly work, she says with a smile, "This screwdriver (JUKUREN) is easy to grip and doesn't require a strong grip force, so it's very easy to use. The work support navigation system is easy to understand, too, so mental and physical fatigue are lighter than when I previously used an electric screwdriver at another site. "

Tohoku Plant also serves as the mother plant of the Ricoh Group. The plant's initiatives are fed back to Ricoh Group sites around the world. Following the adoption of more than 200 units at Tohoku Plant, more than 2,600 units of HIOS “JUKUREN Series” have been adopted at Ricoh Group sites in Japan and overseas, contributing to improving productivity at “manufacturing sites where people work.”

Adherence to products with screws

Ricoh Group is highly environmentally conscious, being the first Japanese company to participate in RE100 (an international initiative to declare that companies will replace the energy they consume in their business activities with 100% renewable energy). Since its foundation, HIOS has emphasized manufacturing that is friendly to people and the environment. HIOS continues developing future-oriented products, and in 2023, received the Encouragement Award at the Eco Pro Award for "contributing to the reduction of environmental impact throughout the product life cycle".

In the universe of Japanese manufacturing, screws have long been referred to as “rice in industry”. Their role has changed from “consumable parts” to key parts that can contribute to the perpetual use of products.