Hitachi Global Life Solutions x HIOS

Taking on the challenge of screw fastening automation and sustainability

for “Japan Quality” home appliances

Hitachi Global Life Solutions has been a leader in home appliance manufacturing in Japan. At its key production site, the Taga Works, updates focused on automation and productivity improvements are being implemented to build more efficient production lines for better product manufacturing. One of the solutions adopted in this manufacturing environment is HIOS's "Screw Fastening Solutions."

Interview01

Taga Works, Hitachi Global Life Solutions (hereinafter referred to as “Hitachi GLS”) began operations in 1939 as Hitachi's first mass production factory for electrical products. Starting with electric fans, the factory has manufactured various products such as vacuum cleaners and word processors, adapting to the needs of each era.

Currently, the factory primarily produces home appliances such as washer-dryers, clothes dryers, vacuum cleaners, rice cookers, and IH cookers, supporting people’s comfortable lifestyles.

The site, spanning an extensive area of 426,316m3, houses the Home Appliance Division, which serves as the core of the company’s home appliance production. It brings together key resources related to manufacturing, including the Production Engineering Department, Manufacturing Department, and Production Management Department.

Japan’s home appliance manufacturers once enjoyed a period of great prosperity. However, with the rise of commoditization, many companies were forced to withdraw from the market, shut down, or scale down their operations. Despite this trend, Hitachi GLS has maintained a strong market share in products such as refrigerators, washing machines, and vacuum cleaners, continuing to deliver high-value-added "Japan Quality" appliances to the world. The source of this competitiveness lies in over 80 years of accumulated expertise in manufacturing and continuous innovation in production technology.

Supporting Hitachi GLS’s manufacturing down to the very last screw is HIOS, a pioneering manufacturer of industrial electric screwdrivers. Since its foundation in 1970, HIOS has specialized exclusively in screw fastening solutions, providing optimal fastening technology to a wide range of industries, from automobiles to precision equipment.

The Taga Works, which manufactures washing machines, vacuum cleaners, and robotic vacuum cleaners, first introduced HIOS screwdrivers in 2015. Kei Shibata, an engineer from the First Manufacturing Department, recalls how they were adopted:

"We were looking for solutions to issues such as screw fastening defects and missed screw fastening in the manufacturing process, so we compared and evaluated electric screwdrivers from various manufacturers. Among them, HIOS’s BLG (JUKUREN® Series), which had just been released at the time, stood out as functionally superior – especially when compared to other products in the same torque range. It offered highly precise detection of screw fastening errors and made it easy to manage the number of screws fastened. That convinced us that it was the right choice, and we decided to introduce it."

Currently, the factory primarily produces home appliances such as washer-dryers, clothes dryers, vacuum cleaners, rice cookers, and IH cookers, supporting people’s comfortable lifestyles.

The site, spanning an extensive area of 426,316m3, houses the Home Appliance Division, which serves as the core of the company’s home appliance production. It brings together key resources related to manufacturing, including the Production Engineering Department, Manufacturing Department, and Production Management Department.

Japan’s home appliance manufacturers once enjoyed a period of great prosperity. However, with the rise of commoditization, many companies were forced to withdraw from the market, shut down, or scale down their operations. Despite this trend, Hitachi GLS has maintained a strong market share in products such as refrigerators, washing machines, and vacuum cleaners, continuing to deliver high-value-added "Japan Quality" appliances to the world. The source of this competitiveness lies in over 80 years of accumulated expertise in manufacturing and continuous innovation in production technology.

Supporting Hitachi GLS’s manufacturing down to the very last screw is HIOS, a pioneering manufacturer of industrial electric screwdrivers. Since its foundation in 1970, HIOS has specialized exclusively in screw fastening solutions, providing optimal fastening technology to a wide range of industries, from automobiles to precision equipment.

The Taga Works, which manufactures washing machines, vacuum cleaners, and robotic vacuum cleaners, first introduced HIOS screwdrivers in 2015. Kei Shibata, an engineer from the First Manufacturing Department, recalls how they were adopted:

"We were looking for solutions to issues such as screw fastening defects and missed screw fastening in the manufacturing process, so we compared and evaluated electric screwdrivers from various manufacturers. Among them, HIOS’s BLG (JUKUREN® Series), which had just been released at the time, stood out as functionally superior – especially when compared to other products in the same torque range. It offered highly precise detection of screw fastening errors and made it easy to manage the number of screws fastened. That convinced us that it was the right choice, and we decided to introduce it."

Easy torque and quantity control.

Implementing HIOS screwdrivers to improve fastening defect rate.

Significant reduction of errors and workload of operators

Interview02

Thus, the HIOS "JUKUREN®" series was introduced into the actual manufacturing site. Daisuke Ebihara, Chief, the First Manufacturing Department, shares the impact of its implementation:

"Since it allows us to manage the number of screws fastened with the specified fastening torque and proper rotational speed, the fastening quality of each screw has improved. It also detects errors including screw floating and come-out in real time, enabling us to maintain stable quality. Additionally, since the screwdriver can transmit a completion signal via serial communication to the production line, it serves as a crucial tool for building a system where the next process cannot start unless the fastening is properly completed."

For operators who handle electric screwdrivers daily, these tools are like an extension of their hands, making ease of use a key factor.

"Most operators say that the JUKUREN® series is easier to use compared to conventional screwdrivers. Other companies’ electric screwdrivers typically have thick, perfectly round grips, whereas the JUKUREN® series features a thinner, oval-shaped grip, which makes it much easier to hold. This has been especially well received by female operators. Additionally, its weight is smaller. Other manufacturers’ products weigh around 700 grams, while the JUKUREN® series is just over 400 grams. Many operators have testified that this significantly reduces physical strain. Another useful feature is the variety of anti-slip grip colors. In workplaces where multiple JUKUREN® screwdrivers are used with different torque settings, these color variations help distinguish them. For example, we assign red grips for a torque setting of 1.0 Nm and green for 0.7 Nm, making identification quick and easy," said Mr. Ebihara.

"Since it allows us to manage the number of screws fastened with the specified fastening torque and proper rotational speed, the fastening quality of each screw has improved. It also detects errors including screw floating and come-out in real time, enabling us to maintain stable quality. Additionally, since the screwdriver can transmit a completion signal via serial communication to the production line, it serves as a crucial tool for building a system where the next process cannot start unless the fastening is properly completed."

For operators who handle electric screwdrivers daily, these tools are like an extension of their hands, making ease of use a key factor.

"Most operators say that the JUKUREN® series is easier to use compared to conventional screwdrivers. Other companies’ electric screwdrivers typically have thick, perfectly round grips, whereas the JUKUREN® series features a thinner, oval-shaped grip, which makes it much easier to hold. This has been especially well received by female operators. Additionally, its weight is smaller. Other manufacturers’ products weigh around 700 grams, while the JUKUREN® series is just over 400 grams. Many operators have testified that this significantly reduces physical strain. Another useful feature is the variety of anti-slip grip colors. In workplaces where multiple JUKUREN® screwdrivers are used with different torque settings, these color variations help distinguish them. For example, we assign red grips for a torque setting of 1.0 Nm and green for 0.7 Nm, making identification quick and easy," said Mr. Ebihara.

Ergonomic design reduces workload, making it easier for women to use.

Monitoring the number of fastened screws to minimize errors.

Intrtorque® & Totupula® Achieving automation without stopping lines

Interview03

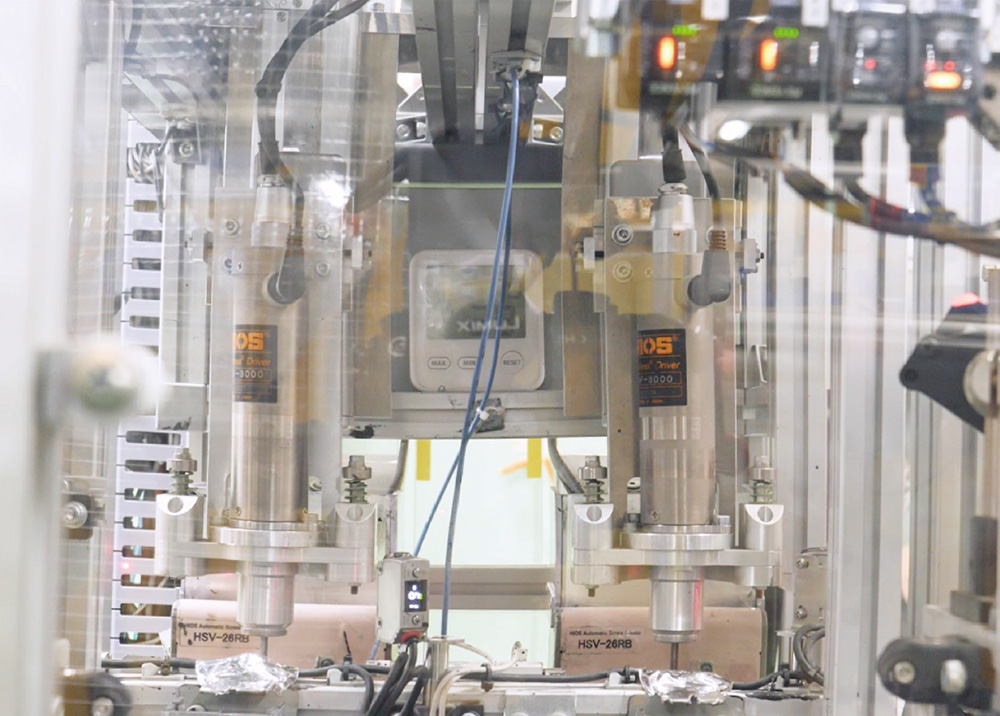

While the electric screwdriver JUKUREN® is utilized for high-quality manufacturing involving manual labor, HIOS’s Screw Fastening Solution is also adopted in automated production lines. HIOS is not only an electric screwdriver manufacturer but also a specialized screw fastening company. The Totsu Screw, developed by the company president Katsuyuki Totsu—who proudly calls himself a "screw geek"—was a groundbreaking innovation at the time of the company's foundation. This screw features a unique indentation in the slot of a traditional straight slot screw, significantly enhancing the fitting precision between the screw and the bit.

Building on this technology, HIOS has developed the Totupula® with an indentation in a cross-head screw, and Intrtorque® with an indentation to star-shaped (Hexalobular) screws. These advanced screw designs have been adopted in the automated production lines of the First Manufacturing Department at Taga Works.

Seiji Yanase from the First Manufacturing Department, who played a key role in developing the automated lines at Taga Works, shares his insights:

"What we wanted to automate in the production line was horizontal screw fastening. While vertical screw fastening is relatively easy to automate, horizontal fastening presents a significantly greater challenge. With conventional screws and automatic screwdrivers, frequent minor stoppages would occur. However, when we tested Intrtorque® screws, these issues were drastically reduced."

However, the adoption of Intrtorque® screws was reconsidered. Mr. Yanase explains the reason:

"Intrtorque® performed remarkably well, but we had some concerns when considering after-sales maintenance. Our home appliances are designed for long-term use, and we have an extensive after-sales service network across Japan. However, distributing specialized Intrtorque® tools to every service technician would be a challenge. So, we tested the Topula® screw instead and found that it delivered results comparable to Intrtorque®. Since Totupula® screws can be maintained using a standard cross-head screwdriver, we decided to adopt them instead."

The production line that adopted Totupula® screws has been operated for over three years with virtually no issues. Meanwhile, for the automation of screw fastening in the motor section of vacuum cleaners, Intrtorque® was chosen.

"Before automation, we manually fastened standard cross-head screws, but because these were small-diameter screws, errors frequently occurred—such as screws tipping over during manual handling and come-out preventing proper torque application. Then, as we automated this process, we introduced Intrtorque®, and the results were outstanding. Come-out no longer occurred and the screws seated perfectly without missing the target because of their excellent straightness. Additionally, after fastening, the screwdriver bit disengages smoothly without sticking, eliminating any operational problems. I was truly impressed by how much of a difference simply changing the screw and bit design could make."

Since Intrtorque® features a specialized shape, some workplaces may be unfamiliar with it. To address this, HIOS recently developed the Intrtorque® Minus. This new design retains the original star-shaped form while adding a straight slot, allowing it to maintain its superior fitting performance while also being compatible with standard straight slot screwdrivers. As an ideal screw for automation—easy to fasten and remove—it is expected to be widely adopted in automated production lines as well as in maintenance and service operations.

HIOS’s commitment to innovation extends beyond screwdrivers to the screws themselves, enabling highly complex screw fastening processes to achieve automation without stoppages.

Building on this technology, HIOS has developed the Totupula® with an indentation in a cross-head screw, and Intrtorque® with an indentation to star-shaped (Hexalobular) screws. These advanced screw designs have been adopted in the automated production lines of the First Manufacturing Department at Taga Works.

Seiji Yanase from the First Manufacturing Department, who played a key role in developing the automated lines at Taga Works, shares his insights:

"What we wanted to automate in the production line was horizontal screw fastening. While vertical screw fastening is relatively easy to automate, horizontal fastening presents a significantly greater challenge. With conventional screws and automatic screwdrivers, frequent minor stoppages would occur. However, when we tested Intrtorque® screws, these issues were drastically reduced."

However, the adoption of Intrtorque® screws was reconsidered. Mr. Yanase explains the reason:

"Intrtorque® performed remarkably well, but we had some concerns when considering after-sales maintenance. Our home appliances are designed for long-term use, and we have an extensive after-sales service network across Japan. However, distributing specialized Intrtorque® tools to every service technician would be a challenge. So, we tested the Topula® screw instead and found that it delivered results comparable to Intrtorque®. Since Totupula® screws can be maintained using a standard cross-head screwdriver, we decided to adopt them instead."

The production line that adopted Totupula® screws has been operated for over three years with virtually no issues. Meanwhile, for the automation of screw fastening in the motor section of vacuum cleaners, Intrtorque® was chosen.

"Before automation, we manually fastened standard cross-head screws, but because these were small-diameter screws, errors frequently occurred—such as screws tipping over during manual handling and come-out preventing proper torque application. Then, as we automated this process, we introduced Intrtorque®, and the results were outstanding. Come-out no longer occurred and the screws seated perfectly without missing the target because of their excellent straightness. Additionally, after fastening, the screwdriver bit disengages smoothly without sticking, eliminating any operational problems. I was truly impressed by how much of a difference simply changing the screw and bit design could make."

Since Intrtorque® features a specialized shape, some workplaces may be unfamiliar with it. To address this, HIOS recently developed the Intrtorque® Minus. This new design retains the original star-shaped form while adding a straight slot, allowing it to maintain its superior fitting performance while also being compatible with standard straight slot screwdrivers. As an ideal screw for automation—easy to fasten and remove—it is expected to be widely adopted in automated production lines as well as in maintenance and service operations.

HIOS’s commitment to innovation extends beyond screwdrivers to the screws themselves, enabling highly complex screw fastening processes to achieve automation without stoppages.

Adoption of Intrtorque®, ideal for automation.

Circular economy driven by a home appliance manufacturer and a manufacturer specialized in screws

Interview04

HIOS’s screw fastening solutions go beyond just ensuring stable fastening and facilitating automation. They also play a crucial role in addressing the environmental considerations increasingly demanded in modern manufacturing.

Production line stoppages and reduced yield rates caused by screw fastening errors can significantly impact productivity and efficient energy use. In this regard, HIOS’s solutions offer a major advantage. Not only do they drastically reduce fastening-related problems, but they also minimize wear on screwdriver bits compared to conventional screwdrivers.

"When Intrtorque® or Totupula® screws are used, the increased contact surface with the bits helps distribute stress during fastening, reducing metal fatigue and significantly lowering the frequency of bit replacements. Additionally, the stable fastening process has improved overall reliability," says Mr. Ebihara.

This level of performance is difficult to achieve with conventional screws and screwdrivers from other manufacturers. In fact, other manufacturing sites that switched from standard cross-head screws and bits to Totupula® screws and HIOS’s bits have reported a more than tenfold reduction in bit replacement frequency.

When repairing, refurbishing, or recycling manufactured products, ease of disassembly is a crucial factor. In this regard, HIOS’s Intrtorque® and Totupula® Screws, designed to be both easy to fasten and remove, are ideal for resource-recycling manufacturing.

Hitachi GLS is actively promoting sustainable manufacturing by decarbonizing its value chain, utilizing renewable energy, and incorporating recycled plastics. Similarly, since its foundation, HIOS has prioritized environmental and safety-conscious product development, including obtaining BELS Certification for its buildings and engaging in carbon offset initiatives.

Both companies' "unique commitment to screws" will drive environmentally friendly manufacturing.

Production line stoppages and reduced yield rates caused by screw fastening errors can significantly impact productivity and efficient energy use. In this regard, HIOS’s solutions offer a major advantage. Not only do they drastically reduce fastening-related problems, but they also minimize wear on screwdriver bits compared to conventional screwdrivers.

"When Intrtorque® or Totupula® screws are used, the increased contact surface with the bits helps distribute stress during fastening, reducing metal fatigue and significantly lowering the frequency of bit replacements. Additionally, the stable fastening process has improved overall reliability," says Mr. Ebihara.

This level of performance is difficult to achieve with conventional screws and screwdrivers from other manufacturers. In fact, other manufacturing sites that switched from standard cross-head screws and bits to Totupula® screws and HIOS’s bits have reported a more than tenfold reduction in bit replacement frequency.

When repairing, refurbishing, or recycling manufactured products, ease of disassembly is a crucial factor. In this regard, HIOS’s Intrtorque® and Totupula® Screws, designed to be both easy to fasten and remove, are ideal for resource-recycling manufacturing.

Hitachi GLS is actively promoting sustainable manufacturing by decarbonizing its value chain, utilizing renewable energy, and incorporating recycled plastics. Similarly, since its foundation, HIOS has prioritized environmental and safety-conscious product development, including obtaining BELS Certification for its buildings and engaging in carbon offset initiatives.

Both companies' "unique commitment to screws" will drive environmentally friendly manufacturing.

From the left to right: Mr. Ebihara, Mr. Shibata, and Mr. Yanase.