HIOS won “Encouragement Award” of the 5th EcoPro Awards for “screw fastening systems” that contribute to reduction of environmental load for the entire product lifecycle

We would like to announce that our “screw fastening systems” won the Encouragement Award of the “5th EcoPro Awards” (sponsored by the Ministry of Finance, the Ministry of Agriculture, Forestry and Fishery, the Ministry of Economy, Trade and Industry, the Ministry of Land, Infrastructure, Transport and Tourism, and the Ministry of the Environment of Japan) hosted by the Sustainable Management Promotion Organization (SuMPO).

About EcoPro Awards

These awards recognize products, services, technologies, solutions, and business models which take into account changes in social and economic situations such as globalization of economy, enactment of the Paris Agreement, establishment of SDGs, and are trusted by businesses, consumers, investors, and other market players in the domestic market, and embedding excellent and concrete cares for the environment. In this way, further development and wider use of such products, services, technologies, solutions and business models will be promoted to realize a more sustainable society.

About “screw fastening systems” of HIOS

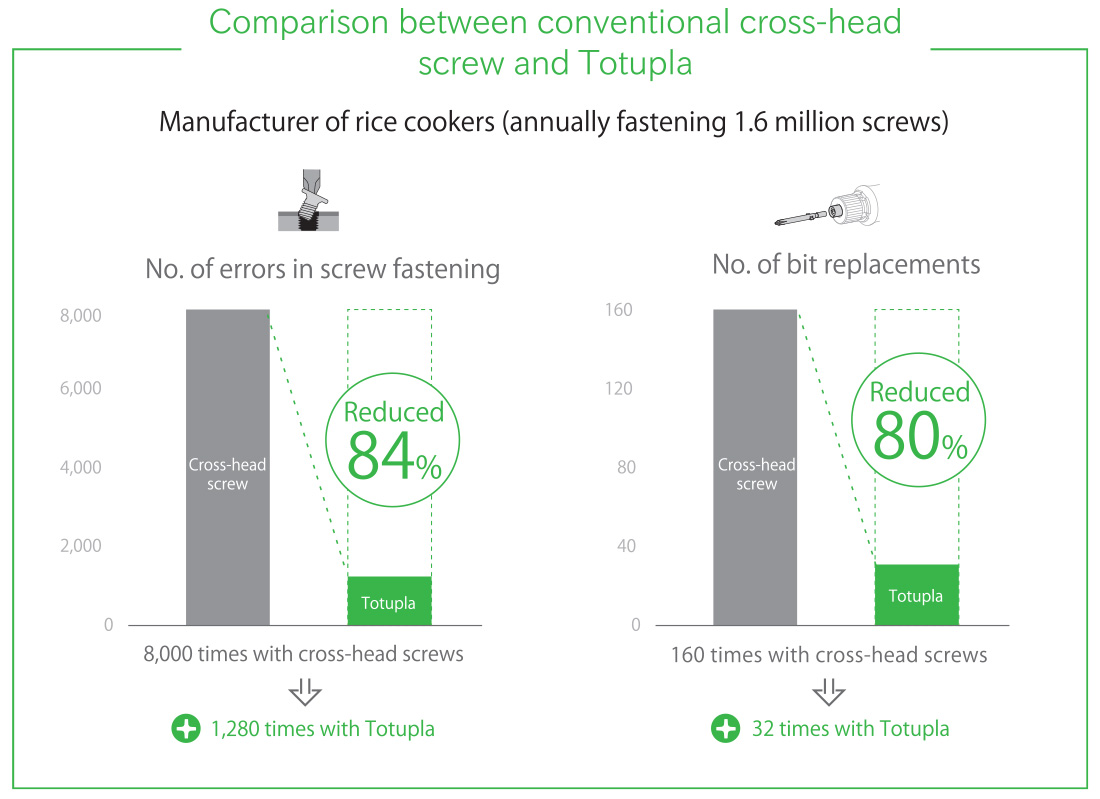

As a comprehensive manufacturer of screw fastening systems, we have developed a wide variety of electric screwdrivers, screws, bits, etc., and expanded our business while taking on challenges related to people and the environment early on. We pioneered energy-saving, operator- and environment-friendly industrial electric screwdrivers and less-carbon particle emission brushless screwdrivers. Totupla and Intrtorque have earned a good reputation for excellent engagement with bits, greatly reduced errors in screw fastening, and being removable for recycling. The dedicated bit wears less and can be used much longer than conventional bits - this also contributes to save costs and resources. We will further evolve ours efforts and contribute to realize a sustainable society.

Why awarded?

●Our screw fastening systems reduce errors in screw fastening and can be easily disassembled for recycling and can be repeatedly reassembled. These factors are effective to realize a circular economy and lead to higher efficiencies in terms of both resource usage and economy. In addition, as the systems are linked with IoT of our new products, they can be great support tools that automatically register and update data of parts assembling using screws and disassembling in implementing a circular economy business model where maintenance, repair, and reuse are involved.

●In HIOS products implement technologies that greatly improve assembly using screws and work control are intensively embedded so that CO2 reduction and streamlining and efficiency of work suitability checks and inspections are achieved.

●In HIOS products implement technologies that greatly improve assembly using screws and work control are intensively embedded so that CO2 reduction and streamlining and efficiency of work suitability checks and inspections are achieved.

EcoPro Awards website

https://sumpo.or.jp/seminar/awards/5th_ecopro_awards.html

https://sumpo.or.jp/seminar/awards/5th_ecopro_awards.html

HIOS screw fastening systems dramatically improve

product life cycle and reduce environmental loads

Improved screws and bits contribute to realizing a circular economy.

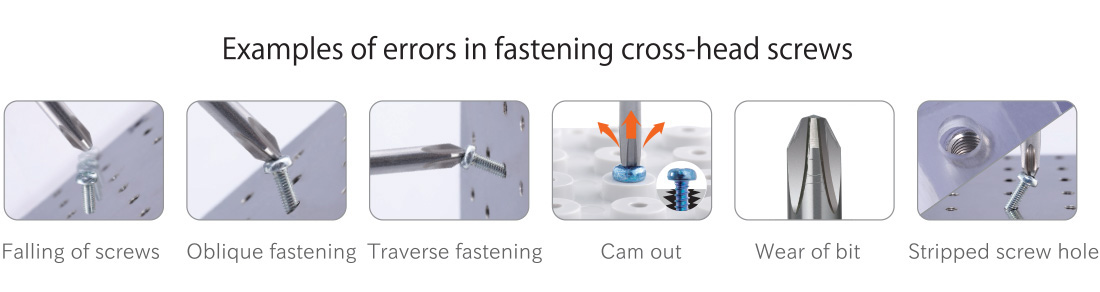

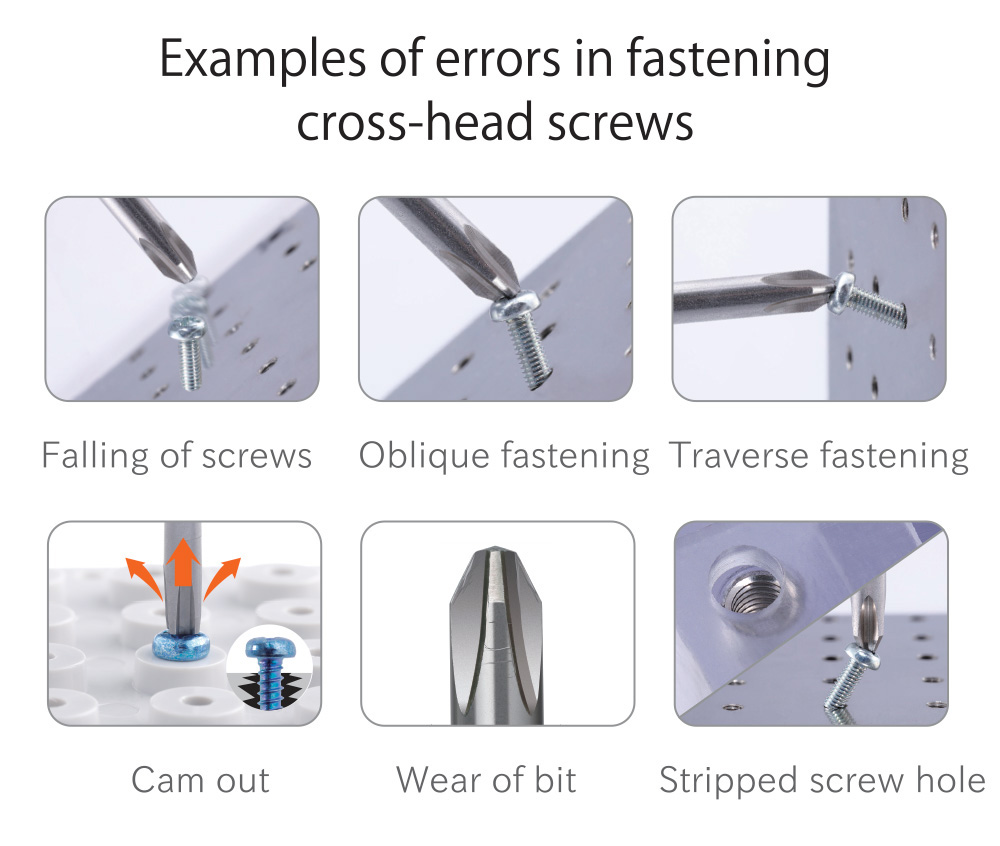

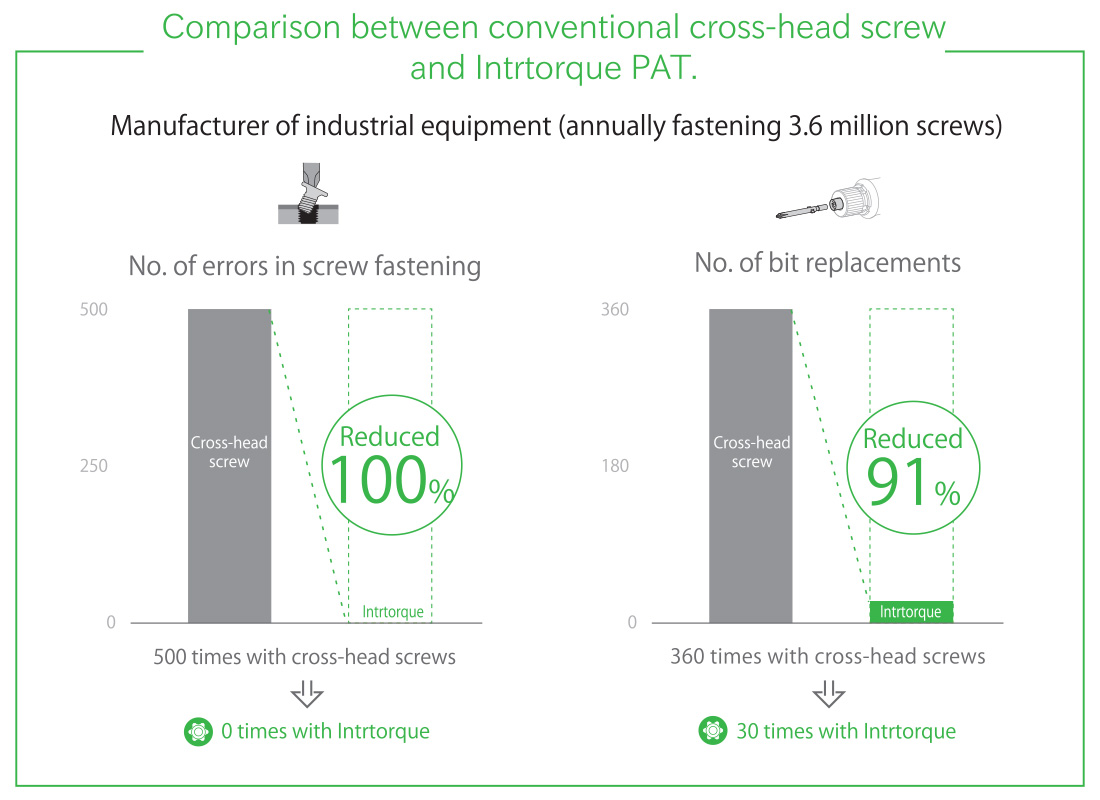

We thoroughly study the shapes of our screws and bits to reduce errors in screw fastening.

Losses caused from errors in screw fastening lead not only to scrapping of screws but also to damage of product parts and even losses of assembly units.

Losses caused from errors in screw fastening lead not only to scrapping of screws but also to damage of product parts and even losses of assembly units.

A user who employed “Totupla” and

“Intrtorque” reduced losses.

We contribute to effective utilization of resources by focusing on 3R.

A screw plays a role of not only "fastening" but also "loosening". The latter role allows us to disassemble and recycle products by removing screws. We will contribute to effective utilization of resources by utilizing screws and promoting 3R (Reduce, Reuse and Recycle). From this perspective, we will build a society in which the economy develops while protecting the environment and resources of the earth.

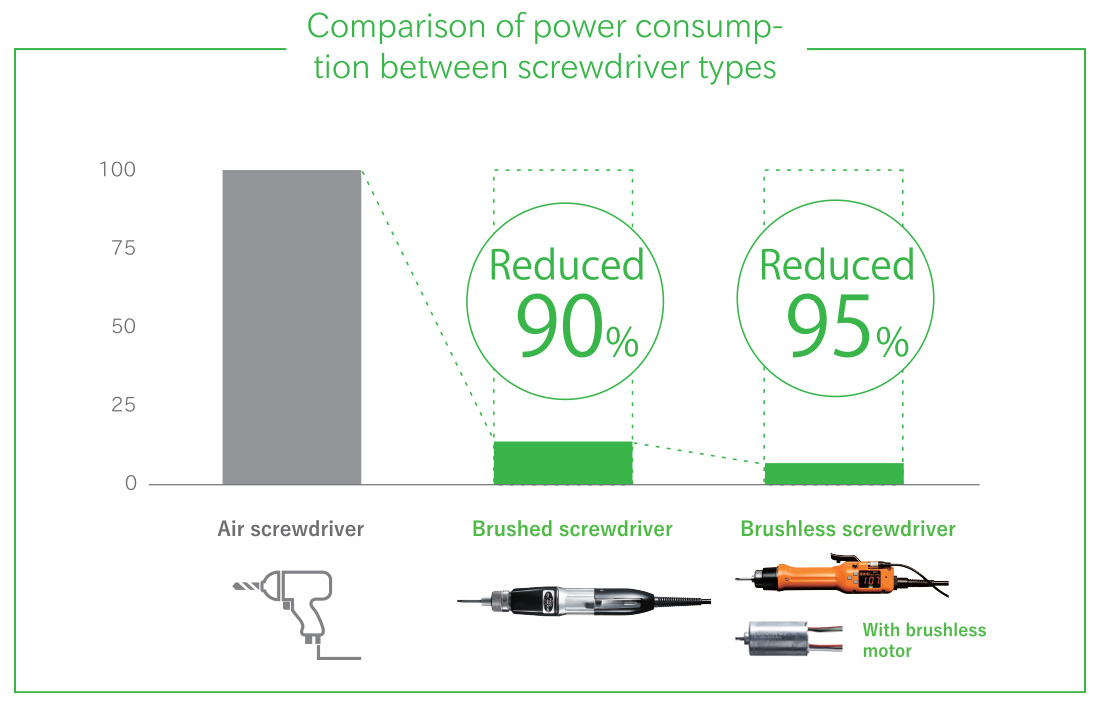

We will contribute to energy saving in the fight against global warming.

Our industrial electric screwdrivers eliminate environmental loads of oil scattering and massive electricity consumption by compressors, and lead to great energy saving and pleasant and clean work environments. Compared with air screwdrivers, brushed screwdrivers reduce power consumption by 90% and brushless screw drivers by 95%.

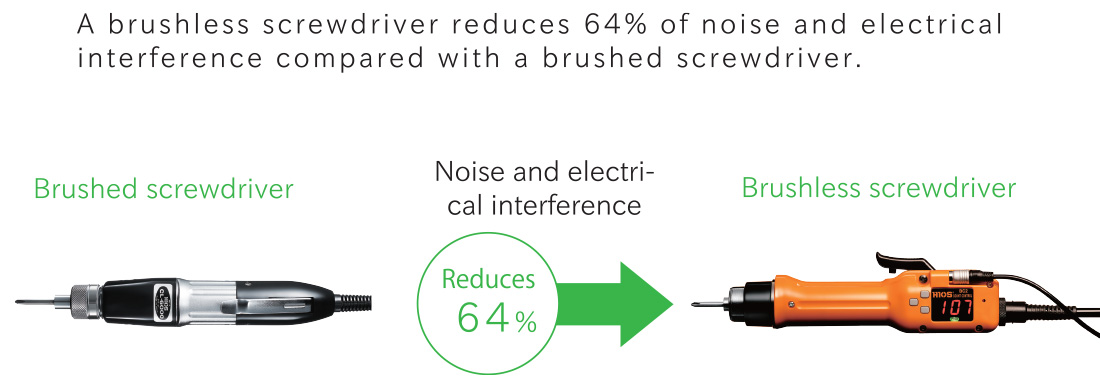

We will contribute to realize clean work environments by reducing

the amount of harmful substances produced.

the amount of harmful substances produced.

A conventional brushed screwdriver requires replacement of its carbon brush semiannually for daily fastening of 5,000 screws. The carbon brush becomes 0.6g lighter when replaced. This means that 0.6g of carbon particles, which are harmful substances, accumulate in a screwdriver or scatter in the air.

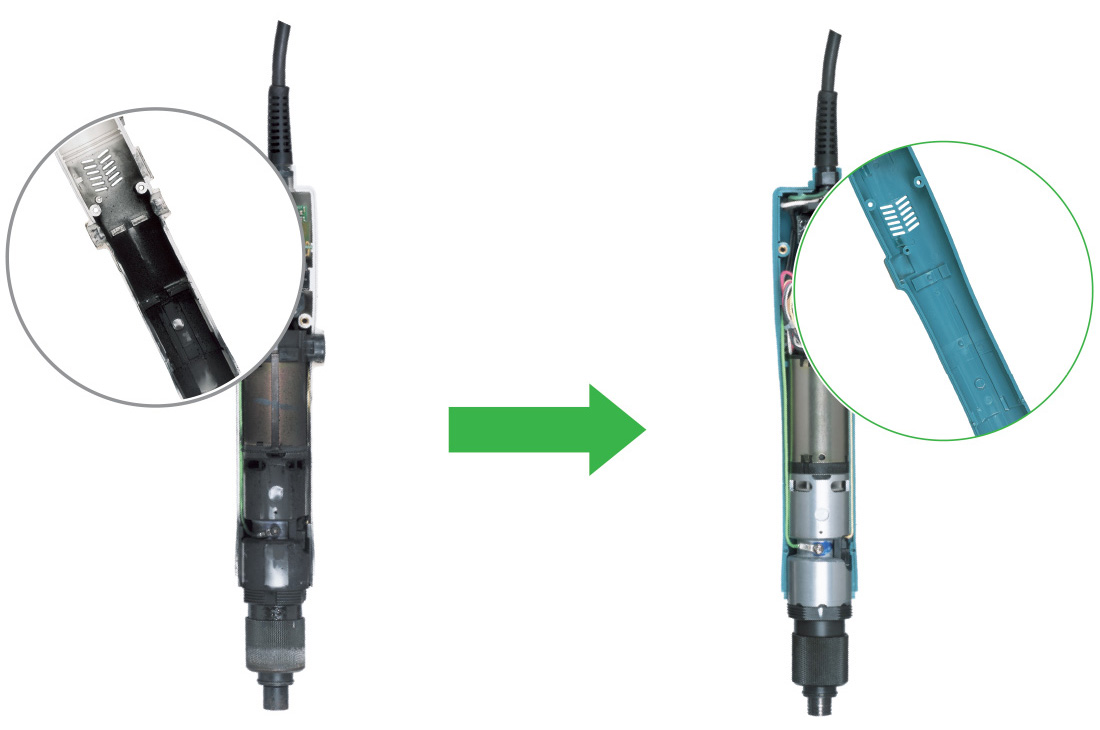

Precision instrument manufacturers who consider carbon particles and noise as problems and manufacturers who try to create safe work environments are actively employing brushless screwdrivers. HIOS also focuses on development of brushless screwdrivers to help to create clean work environments. This also leads to energy saving and improves durability of assembled products.